| Incoterm: | FOB |

|---|---|

| Min. Order: | 1 Set/Sets |

Basic Info

Generator Type: Alternator

Output Type: AC Three Phase

Certification: CE, ISO

Standard: Standard

Additional Info

Packaging: In cases

Brand: QNP

Transportation: Ocean,Land

Place of Origin: China

Certificate: ISO9001,CE

Port: Qingdao Port,Shanghai Port

Product Description

High Efficiency Turbo Generator QNP:

A steam turbine generator is a device that uses steam to rotate a turbine generator to produce electricity.Steam turbines use water that is heated to extremely high temperatures and converted into steam to rotate the blades of a turbine, in order to create mechanical or rotational energy.

This rotational energy caused by the high pressured steam turbine is used to generate electricity in an attached generator. Steam turbine generators require an outside fuel source to heat water into the steam needed for electric production.

QNP`s steam turbine generator can adopt static silicon controlled excitation, two-pole AC brushless excitation and three-pole AC brushless excitation.

Models

Mainly produce the following models of steam turbine generator and the specifications are as follows:

| Model | Voltage (KV) | Frequency (Hz) | Power (MW) |

| 2 Poles Steam Turbine Generator | 6.3-3.8 | 50 | 3-60 |

| 6.6-13.8 | 60 | ||

| 4 Poles Steam Turbine Generator | 0.4/0.69 6.3/6.6 10.5/11 | 50 | 0.5-30 |

| 0.4-11 | 60 |

Company Overview:

Located in the Qingzhou city of Shandong province, QNP(QingNeng Power)has developed into the largest leading private manufacturer of steam turbines and generators in China, covering an area of 200,000 square meters with building area of 90,000 square meters. We have subsidiaries in Indonesia and Beijing, as well as a branch office in Shanghai.

QNP has passed such certificates as CE, ISO9000, ISO14001 and OHSAS18001.

Our Product & Service:

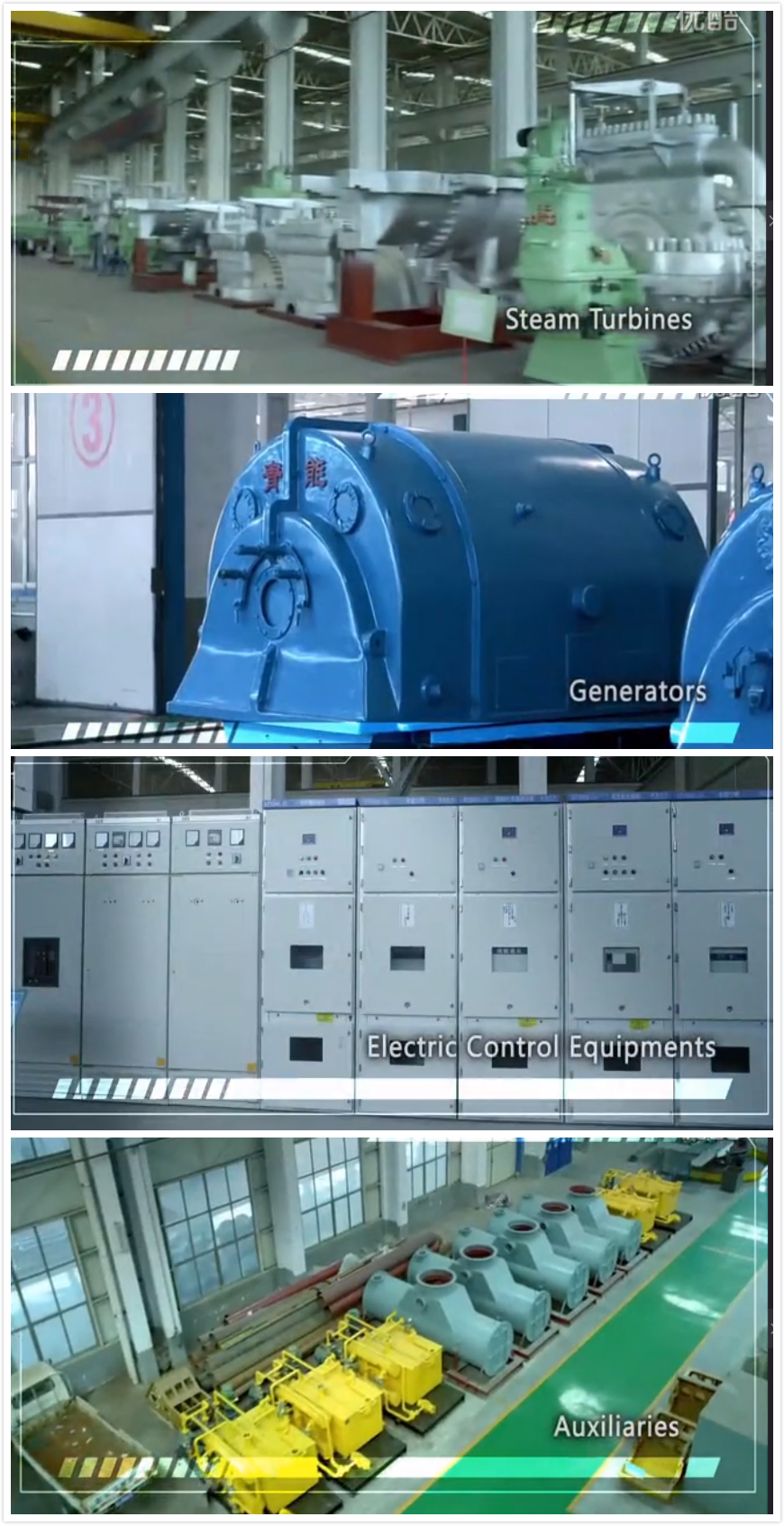

QNP`s main products include steam turbines, generators, electrical control equipment, water treatment equipment and other relevant products.

Manufacturing steam turbine, generator (≤100MW)with I&Cl system, electrical panels & switchgears, spare parts and etc. Providing 1~1000MW Overhaul & Commissioning, Energy Saving Reform and Upgrading, Operation Supervision Service for Power Plant and so on. Contracting Power Plant Turn-key Project.

QNP manufactures various steam turbines. At present, we mainly focus on the research and promotion of single layout and packaged steam turbines, as well as High speed & high efficiency steam turbines.

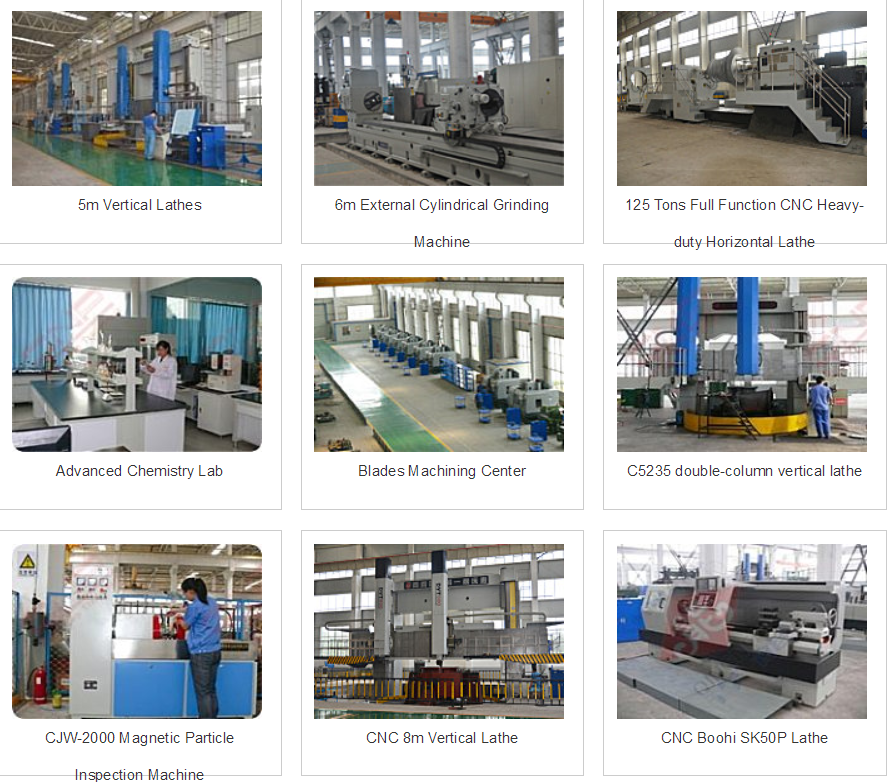

Manufacturing and Capacities:

With strong manufacturing and machining capacities, main parts and key components of our products are made by CNC machines. More than 400 types of advanced equipment with high accuracy, strong reliability and advanced machining processes are available with QNP, such as the Mitsubishi Planer five sides machining center, the Italy horizontal slotting machine, the 10 meters CNC heavy duty horizontal lathe, the 8 meters vertical lathe, the 6 meters CNC grinding machine, the CNC gantry milling and drilling machine, the CNC gantry wrapping machine and the winding machine for generators. The components are standardized and modularized with enhanced universality and compatibility.

Our state of the art quality test center consists of a physics lab, a chemistry lab, a chemical analysis lab, a precision measurements lab and a metrology lab. The high speed dynamic balancing test machine can test rotors at speeds up to 15000 rpm. The Steam Turbine trial platform can do load tests and performance verification tests. Other instruments such as our German direct-reading spectrometer, tri-linear coordinate measuring instrument, and our speed test platform provide reliable assurance of product quality.

Project Cooperate With Us:

Sales Network & After Sales:

The market share of QNP is growing steadily and rapidly. Our agents and products have a presence in many countries and regions all over the world such as the U.S.A, Canada, Brazil, Argentina, Russia, Australia, Serbia, India, Indonesia, Pakistan, the Philippines, Thailand, Cambodia, Vietnam, Iran, Myanmar, as well as Sudan, Morocco and Algeria in Africa.

QNP has a skilled and experienced After Sales team geared up for fast response and superior services to our customers at any time. Our Long distance monitoring center is equipped to monitor, diagnose, serve and manage the units delivered. QNP also provides technical training to our customers at regular intervals.

© 2019 CHINA WAY. All Rights Reserved. Shandong Qingneng Power Co., Ltd., Inc. All rights reserved. site map. sitemap.html